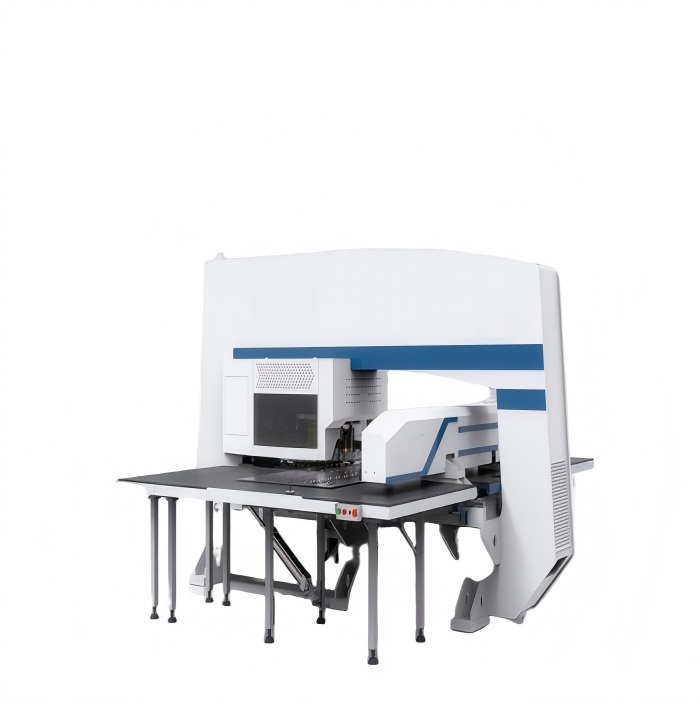

Profile Bending Machine

Profile Bending Machine For Sale

Profile bending machine is a specialized and efficient processing equipment used for bending various shaped materials such as angle steel, channel steel, I-beams, flat steel, square pipes, and round pipes. It can complete the end pre bending of various profiles, roll circular and curved work pieces, and is widely used in industries such as aerospace, petrochemical, hydro power, shipbuilding, automotive manufacturing, mechanical manufacturing, and steel structure construction.

Profile bending machine has a curved downward adjustment structure, with the upper roller shaft fixed and the two lower roller shafts moving up and down in an arc around a central axis relative to the upper roller shaft. Its main function is to pre bend the end of the profile and make it bend and deform. At the same time, the two lower roller shafts are also the main transmission shaft, driven by a hydraulic motor, to roll and shape the bent and deformed profile. To prevent distortion and deformation of profiles during the bending process and improve the bending accuracy of profiles, two rollers and rollers are added, which can move vertically up and down to adapt to different specifications and bending radii of profiles.

W24S 3 Roller CNC Hydraulic Profile Bending Machine For Sale

W24S profile roll bending machine is an important metal processing equipment, widely used in various fields. The profile bending machine can handle different types and sizes of profiles, including angle steel, channel steel, I-beam, T-beam, etc., and has strong adaptability.

Main Features

ⅠRolls are hardened & made from high quality steel.

Ⅱ.Drive shafts are hardened and ground with double taper roller bearing support.

Ⅲ.Machine can be set up in horizontal or vertical working position.

Ⅳ.Hydraulic lateral angle guide rolls,double pinch hydraulic forming rolls.

Ⅴ.Dual adjustable lateral guides Rolls are driven via 3 separate hydraulic motor lower rolls hydraulic moveable up and down.

Ⅵ.Perfectly complete pre-bending,rolled-up,roll calibrate.

Ⅶ.Three rollers are powered.Working principle: two down rollers as main driving roller,or all three rollers as main driving roller, with upper roller fixed and two down rollers do up-and-town movement around one fixed center. Triple geared drive,low voltage driver, low current consumption and high efficiency.Well hydraulic control,displacement liquid-crystal display with accuracy ±0.1mm.

Ⅷ.The two touch steel stick can permit the good finishing quality of asymmetric plate section bending.

Ⅸ.Advanced and compact structure with full function.

Ⅹ.The machine has six oil tanks(two big oil tanks,four small oil tanks),and the head is vertically.The yield strength bend profile with 250Mpa (Max.).

Ⅺ.Full function,complicated structure,high precision and very stronger.

Ⅻ.Roving foot pedal control with emergency stop.

|

Model&spec. |

W24S-6 |

W24S-16 |

W24S-30 |

W24S-45 |

W24S-75 |

W24S-100 |

W24S-140 |

|

|

Max bending modulus of section (cm3) |

6 |

16 |

30 |

45 |

75 |

100 |

140 |

|

|

Bending speed(m/min) |

5.5 |

5.5 |

5.5 |

5.5 |

5 |

5 |

5 |

|

|

yield limit of material (MPa) |

245 |

245 |

245 |

245 |

245 |

245 |

245 |

|

|

inward bending of angle steel |

The max cross section (mm) |

50×5 |

80×8 |

90×10 |

100×10 |

120×12 |

140×16 |

150×16 |

|

The min bending diameter (mm) |

800 |

1000 |

1200 |

1500 |

2000 |

2500 |

2400 |

|

|

The min cross section (mm) |

20×3 |

30×3 |

35×3 |

36×5 |

38×4 |

40×5 |

50×5 |

|

|

The min bending diameter (mm) |

400 |

550 |

560 |

600 |

600 |

720 |

1000 |

|

|

outward bending of angle steel |

The max cross section (mm) |

50×5 |

80×8 |

90×10 |

100×10 |

120×12 |

140×16 |

150×16 |

|

The min bending diameter (mm) |

800 |

1000 |

1100 |

1300 |

1600 |

1800 |

2200 |

|

|

The min cross section (mm) |

20×3 |

30×3 |

35×3 |

36×5 |

38×4 |

45×5 |

50×5 |

|

|

The min bending diameter (mm) |

400 |

550 |

500 |

600 |

700 |

760 |

400 |

|

|

outward bending of channel steel |

channel steel model |

8 |

12 |

16 |

20 |

25 |

28 |

30 |

|

The min bending diameter (mm) |

600 |

800 |

800 |

1000 |

1100 |

1100 |

1200 |

|

|

inward bending of channel steel |

||||||||

Send your message to us: