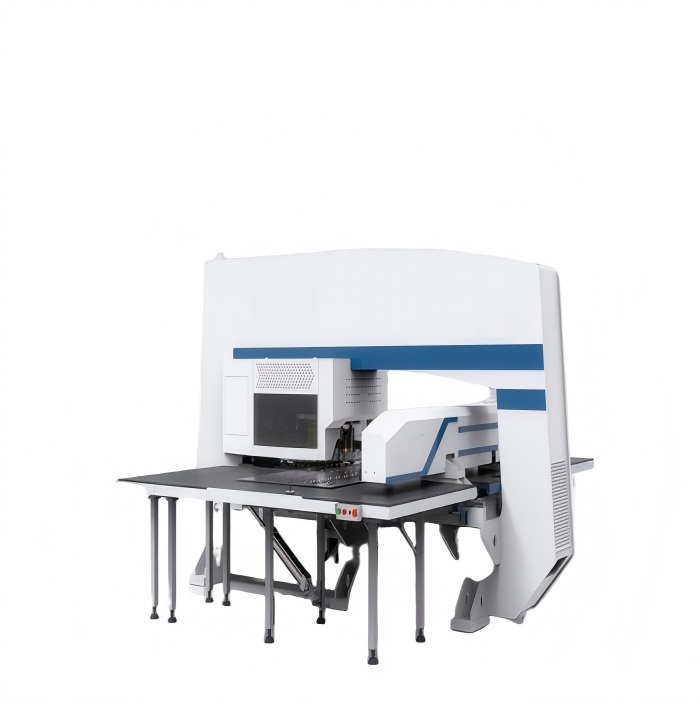

Press Brakes

PRESS BRAKE HYDRAULIC Mdlo.WC67Y

Equipped as standard with E21

BST Mdlo WC67Y hydraulic Press Brake; They are manufactured in CHINA at the Factory located in NANTONG. BST hydraulic Press Brakes are manufactured with the best components of the national and international market, with a modern and robust design, with the experience that gives us more than 30 years in the sector the permanent contact with our customers giving solution to the new needs. that pose us and a perfect verification system of each machine in each of its manufacturing processes, make our machines one of the best in the market

. All our machines are factory tested before delivery, for quality control and a minimum of 72 hours of shooting. This guarantees a perfect operation of the machine from the first day in the client’s house

BST Press brake Mdlo WC67Y:After many years of experience and R&D studies; We can offer you a hydraulic press brake

Folding software for technical office in 2D with: Introduction to grades, extensive library of tools and materials, search for the development of the material to be cut, search for the order of folding. Import.

The C.N can optionally also control the R-axis, the bending compensation table and the folding power.

As standard, it is equipped with a 135 mm high punch, multiple die with a “V” of 30º,

Rear stop, with height-adjustable carriage, folding and micrometric fingers,

Block and Hydraulic System withy: Normative CE, operating redundancy valves of exclusive BSTdesign, which provides the machine with maximum reliability, safety and simplicity in handling .

Great, gooseneck, removable table and screwed to the bottom plate.

Optionally, manual or CNC flexion compensation table, motorized or hydraulic. Front and rear protections by level 4 safety barriers.

Front arms of sheet support.

Machine capacities:

From 1100 to 7100 of bending length And from 30 to 1,000 tons. Bending power

Optional:C.N. 2-axis E21 with graphic video, and the same features as the Office Software, Matrices, punches, special measures we adapt the machine to your needs

Electric material:

Electrical and electronic components only of the main international brands, with the sole purpose that, in the absence of any element, it can be found anywhere in the world and be compatible with another brand.

All emergency stops and safety barriers are connected to a safety module that controls them and are connected to a Reset button located on the control box.

With the best possible technological advances at a Priceand unbeatable quality.

Send your message to us: